Maximize Warehouse Density Without Sacrificing Selectivity

Storage capacity constraints pose a significant challenge for many warehouse operations. If you’re seeking ways to store more inventory in your existing space, pushback rack systems offer an intelligent solution that balances density with accessibility.

Massey Rack provides high-quality pushback racking that can dramatically increase your storage capacity – often doubling or tripling your pallet positions compared to standard selective racking. Our systems deliver exceptional value while maintaining the product selectivity your operations require.

What Are Pushback Rack Systems?

Pushback rack systems represent an ingenious balance between selectivity and storage density. These gravity-fed systems use a series of nested carts on inclined rails to store multiple pallets deep while maintaining front-aisle access.

Unlike drive-in racks that require forklift entry into the rack structure, pushback systems keep operations at the aisle face. When placing a pallet, it gently “pushes back” any existing inventory deeper into the lane. Upon retrieval, gravity automatically brings the next pallet forward to the pick position.

This Last-In-First-Out (LIFO) configuration maximizes your storage capacity while preserving excellent inventory visibility and access, making it ideal for operations with multiple SKUs requiring dense storage.

Our Pushback Rack Solutions

At Massey Rack, we offer custom-designed pushback systems that accommodate between 2-6 pallets deep per lane. Each system is engineered to your specific requirements, inventory profile, and facility constraints.

Key Components of Our Pushback Systems

-

Heavy-Duty Cart Assemblies

Robust nested carts with sealed bearing wheels provide smooth operation and long service life

-

Precision Rails

Engineered with the optimal pitch to ensure controlled pallet movement during loading and unloading

-

Structural or Roll-Formed Frames

Available in different configurations to match your load requirements and budget

-

Safety Features

Includes cart stops, impact guards, and load guards to protect both inventory and personnel

Customer Success with Pushback Racks

Our customers love the quality and reliability of our pushback racks. Check out the reviews to see what they have to say about working with us.

Why Choose Pushback Racking?

When evaluating high-density storage options, pushback racks offer distinct advantages for specific inventory profiles and operational requirements:

Benefits of Implementing Pushback Systems

Dramatic Space Utilization

Reduced Aisle Requirements

Improved Forklift Productivity

Superior Selectivity

Reduced Equipment Damage

Ideal Applications for Pushback Racking

Pushback systems excel in specific warehouse scenarios where both density and selectivity matter:

When Pushback Makes Sense

Multiple Pallets Per SKU

Limited SKU Variety

Non-Date-Sensitive Inventory

Space-Constrained Facilities

High-Throughput Operations

Professional Installation & Support

Proper installation is crucial for the safe and efficient operation of pushback rack systems. Our experienced installation teams:

- Coordinate closely with your operations to minimize disruption

- Follow manufacturer specifications for precise alignment and pitch

- Conduct comprehensive load testing prior to handover

- Provide operator training to ensure safe system use

- Offer ongoing support and maintenance services

We understand that downtime costs money, which is why our installation process is streamlined for efficiency without sacrificing quality or safety. From initial design through final implementation, we maintain clear communication and stick to agreed timelines.

Frequently Asked Questions About Pushback Racks

How does a pushback rack system work?

What's the difference between pushback and drive-in racking?

How many pallets deep can pushback racks store?

Is pushback racking suitable for all inventory types?

What maintenance do pushback systems require?

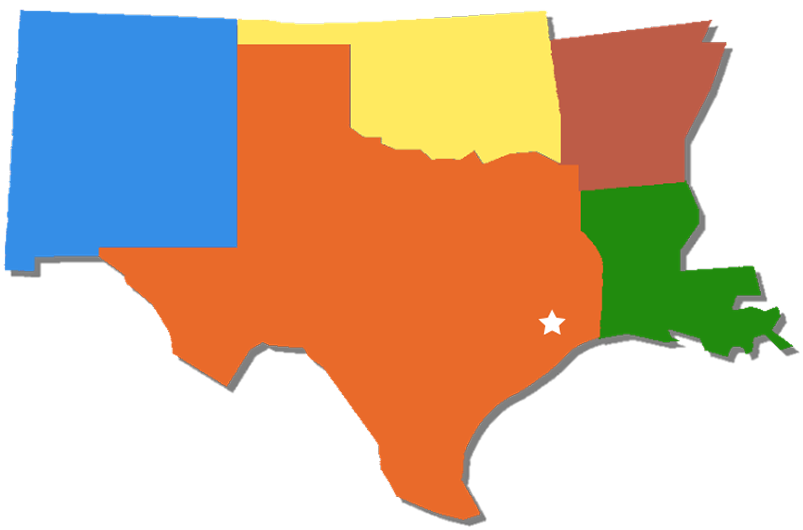

Pushback Rack Installation Throughout Texas & Beyond

Local Expertise. Regional Coverage. We’ve been designing and installing high-density storage solutions across Texas and neighboring states for years. Our Houston-based teams deliver professional installation services that meet all safety standards while maximizing your storage density.

Transform Your Storage Capacity Today

Ready to explore how pushback rack systems can maximize your warehouse capacity? Our storage specialists can assess your current setup, inventory profile, and operational requirements to determine if pushback racking is right for you.

We offer both new and used pushback systems to accommodate different budget requirements without compromising on quality or safety. Contact us today for a no-obligation consultation and quote.